Yoshikane Knives | Hand-Forged Traditional Japanese Knives

Time to read 7 min

Time to read 7 min

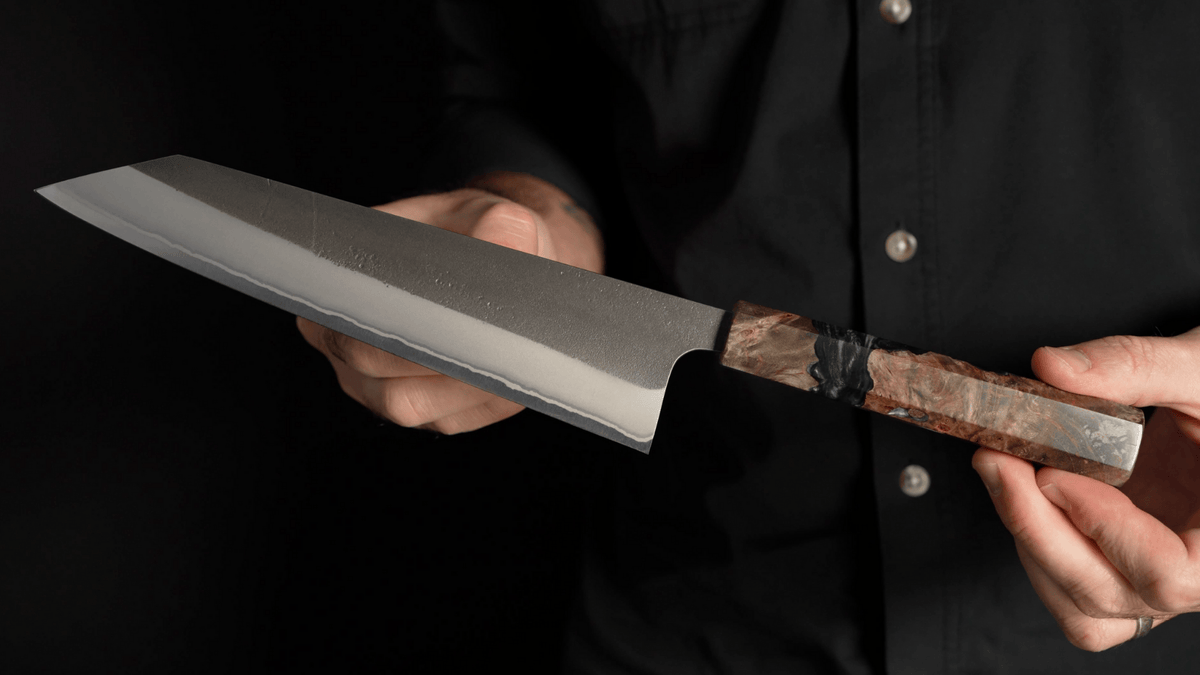

When it comes to hand-forged Japanese knives, few names resonate with the same reverence as Yoshikane Hamono. Based in Sanjo City, Niigata Prefecture, an area renowned for its blacksmithing tradition, Yoshikane has been producing knives for over four generations, dating back to 1919.

Known for their exceptional geometry, meticulous heat treatment, in-house sharpening, and signature pinch grip comfort, these knives are a mainstay for both professional chefs and proficient home cooks.

In this blog, we'll take a detailed look at:

Whether you're upgrading your first Japanese knife or adding another handcrafted gem to your collection, Yoshikane offers something truly timeless.

All images are linked, so if you see something you like, simply tap or click to be taken to the knife or collection.

Table of Contents

Yoshikane primarily works with two steel cores: Shirogami #2, also known as White Carbon Steel, and their proprietary SKD12 semi-stainless steel. Both cores are crafted with expert-level heat treatment, resulting in a Rockwell hardness of 62–64 with incredibly fine geometry.

Shirogami #2 Carbon Steel

Yoshikane's Shirogami blades are hand-forged with a san mai construction, meaning the carbon steel core is sandwiched between two layers of stainless steel cladding. The stainless cladding protects the carbon steel core, minimizing rust management to only the exposed edge. Like all carbon steel knives, they must be kept dry during longer prep sessions, and hand-dried immediately after washing. With proper care, a beautiful patina will develop at the edge up to the cladding line.

Originally, the Shirogami knives featured a Nashiji (pear skin) finish with a kasumi (hazy) mid blade, giving the majority of the blade a cloudy, matte aesthetic with texture from the forging process. However, moving into 2025 and beyond, Yoshikane has committed to exclusively finishing their Shirogami knives with a fine Kurouchi. This Kurouchi isn't the traditional rustic black you might find on other Japanese knives. Instead, it's more refined; some might even call it a "black Nashiji" or "polished Kurouchi." Texturally, it's identical to their nashiji finish, but with a slightly darker color.

Functionally, both finishes perform identically; the change is purely aesthetic. So whether you're holding a Nashiji or a Kurouchi version, expect the same scalpel-like sharpness and food release you'd expect from any Yoshikane knife.

SKD Semi-Stainless Steel

For those seeking a maintenance option closer to the stress-free nature of stainless steel, Yoshikane's SKD Semi-Stainless Steel Core provides a perfect bridge. Also, San Mai, with stainless cladding, Yoshikane's SKD is a proprietary blend that offers a semi-stainless core, meaning it will still patina, but not as aggressively or quickly as shirogami carbon steel. Some of the SKD knives in our personal collections here at C+M took months to show any signs of "patina", and not once have we witnessed any rust spotting. Granted, we take extra care of our carbon steel knives, but rest assured, the SKD is easier to maintain.

We have also noticed that the edge retention of the SKD knives may be marginally better than Shirogami, but the difference is minute. In blind usage, most wouldn't notice unless they were prepping with each blade back to back for a few long prep seshes.

Yoshikane's SKD knives only come with a Nashiji finish. Before the fine kurouchi finish of the Shirogami series, it was nearly impossible to tell the SKD apart.

Yoshikane knives all feature stick tangs that fit into traditional Japanese Wa handles. Yoshikane's handles are octagonal in shape, do not have a bolster, and are all symmetrical (no D-Shaped Wa handles). Any of the 8" / 210mm or larger blades will have a traditional Japanese blade leaning balance, due to the lightweight handle.

The handles themselves vary depending on the series, order received from Yoshikane, and possibly some in-house outfitting from here at C+M.

If you see a handle style you like, act fast, as there's no guarantee that the same handle will be available in the next batch. Additionally, if you find a knife you like that is currently out of stock, consider signing up for email notifications. Even if the handle isn't the same, you'll receive a notification when the blade style is available again.

What sets Yoshikane knives apart, even among other hand-forged Japanese blades, is the feel at the pinch grip.

At the junction where the blade meets the handle, Yoshikane forges a wider tang that then subtly tapers into the rest of the blade past the knife's heel. This flared area creates a broader, more comfortable pinch grip area. Add to that a rounded spine and choil, and the result is one of the most ergonomic pinch grips in the knife world. Even on smaller knives, such as the 5.9" Petty, the flare is evident and functional. It reduces finger and wrist fatigue during long prep sessions and feels more secure in the hand without any aggressive edges digging into your fingers.

These nuanced details in the forging and finishing processes are what make Yoshikane knives so loved. Let's put it this way, you can't just have one in your collection!

Cutting Boards:

Regardless of the steel, Yoshikane blades are very thin behind the edge, and the geometry is extremely fine. Because of this, they should always be used on soft cutting boards, specifically those rated under 1,000 Janka. Ideal options include:

Learn more about the best cutting boards for Japanese knives.

Cutting Techniques:

Yoshikane knives are designed for tap and push chopping, as well as slicing. The fine edge isn't intended for the European-style rock chop or cross chopping when mincing. It's not just about the Rockwell Hardness; it's about the geometry. If you are experienced with Japanese knives, have a proper soft board, and understand a delicate touch with a blade, you can rock chop, as long as the cuts are shallow and minimal force is used.

Honing & Sharpening:

For optimal edge retention, use a leather strop after each preparation session. We ONLY recommend using a Whestone when sharpening Yoshikane knives. Unless you damage the blade or forget to hone it regularly, a 1,000 git whetstone will bring the blade back to life. If you really want to keep the blade out of the box sharp, run it along a 5,000-grit stone using the stropping technique after every other prep session.

Cleaning:

Whether you have a Shirogami or SKD blade, learn to get in the habit of wiping the blade down with a towel while prepping, ideally between ingredients. Hand-wash the blade and handle only, and dry immediately.

Pro tip: Since moisture can linger around the tang and sometimes within the nashiji or kurouchi finish, it's best to let the blade rest on a counter for a bit before putting it on any magnetic easel or strip.

At CutleryandMore.com, we prioritize sourcing a diverse range of handle styles and blade styles to offer the most comprehensive selection of Yoshikane knives in the U.S. Due to their small-batch nature, stock levels fluctuate frequently, and when they're available, they sell out quickly.

Finally, a fair warning: Yoshikane knives will change the way you think about knives!

Broadcast uses cookies to improve your browsing experience.